Maintenance: Equipments: Work Centers

Purpose

This document covers the process of configuring Work Centers for use in the Maintenance application of Odoo 16.

Process

To get started, navigate to the Manufacturing app.

Enable Work Orders

A Work Center is a physical location within your company where different manufacturing processes are done. Odoo gives us the ability to measure our work center's performance and efficiently route our products from the Bill of Material (BOM) throughout its manufacturing process to the appropriate work center(s).

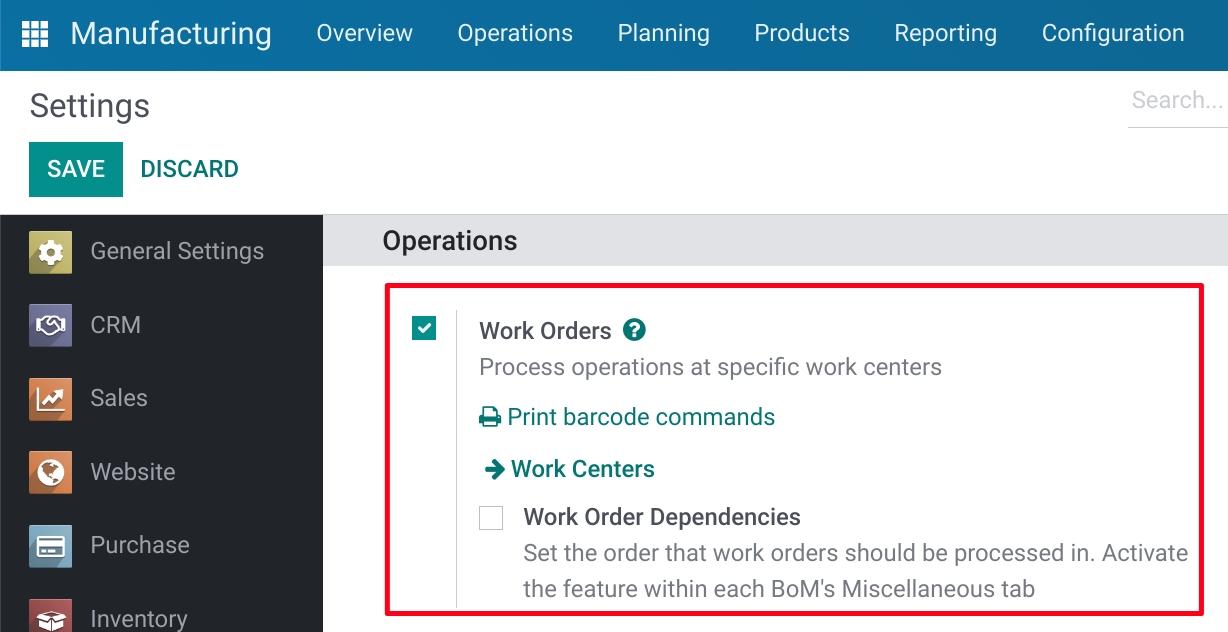

On the top menu bar, go to Configuration > Settings. Here you are going to want to tick the Work Orders option and Save.

Work Centers for Maintenance Requests

Now that we have enabled this option, we will be showing you how a work center can also be created and used from the Maintenance app for processing a maintenance request for company equipment.

Let's navigate to the Maintenance app.

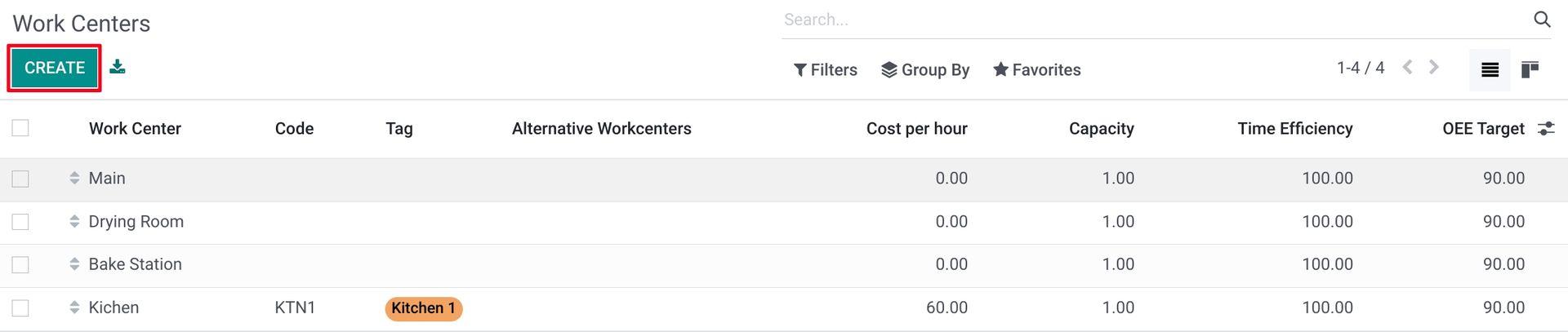

From the top menu, click on Equipments > Work Centers and click NEW.

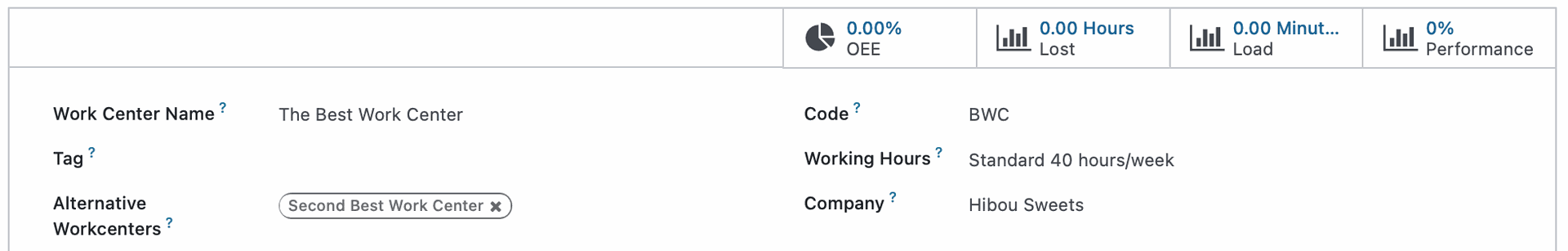

Work Center Name: Work center name.

Alternative Work Centers: Alternative work center(s) that can be substituted to this one in order to dispatch production when the main work center is busy.

Code: Work center code.

Working Hours: Define the working hours of this work center.

Company: Indicate which company this work center belongs to if multi-companies are set.

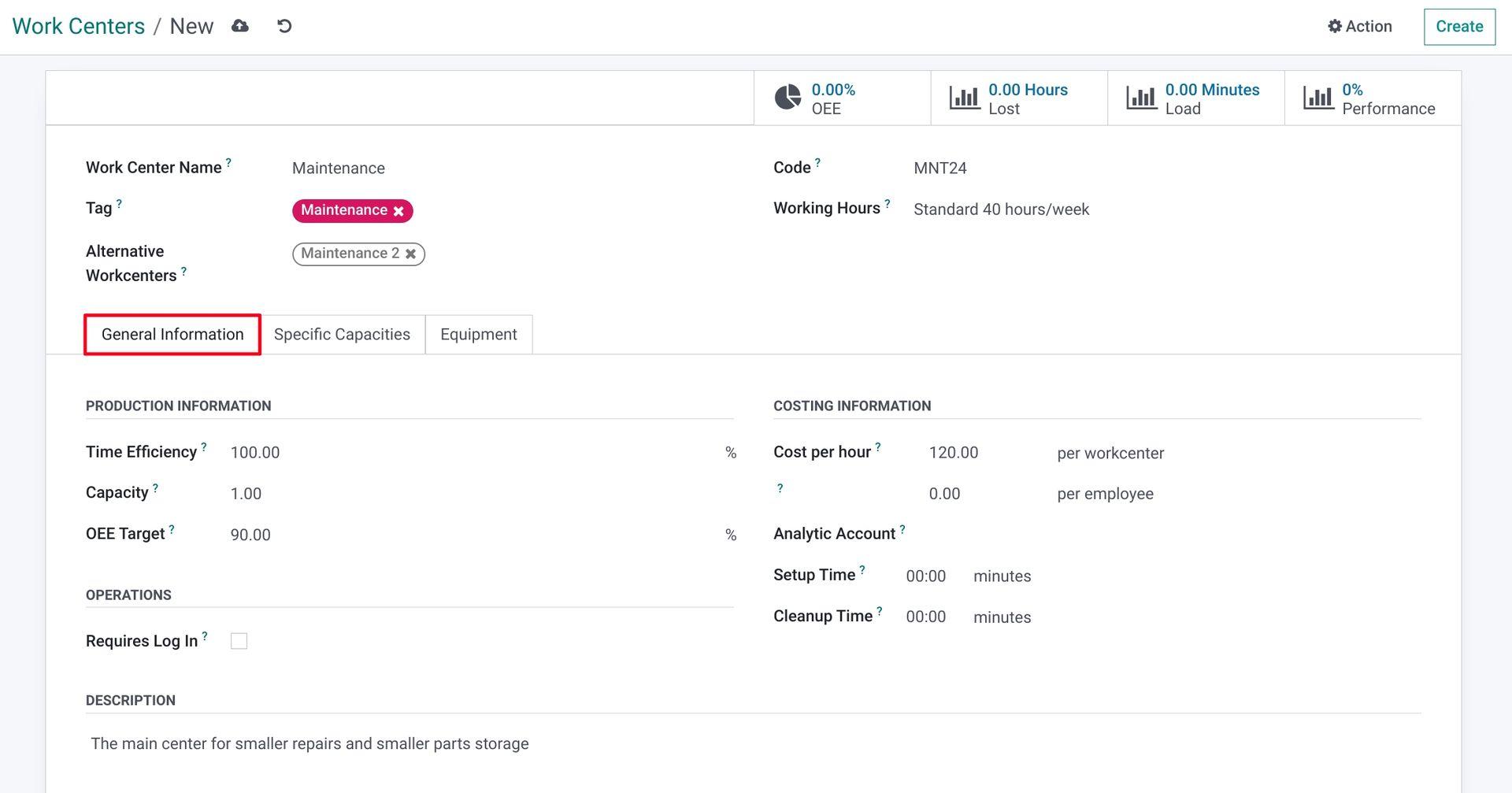

Under the General Information tab:

Product Information

Time Efficiency: This field is used to calculate the expected duration of a work order at this work center. For example, if a work order takes one hour and the efficiency factor is 100%, then the expected duration will be one hour. If the efficiency factor is 200%, however the expected duration will be 30 minutes.

Capacity: Number of pieces that can be produced in parallel. In case the work center has a capacity of 5 and you have to produce 10 units on your work order, the usual operation time will be multiplied by 2.

OEE Target: Overall Effective Efficiency Target in percentage.

Time before prod: Time in minutes for the setting up before the production process.

Time after prod: Time in minutes for cleaning up after the production process.

Description

Here you can give a description of the Work Center. This can be as detailed as you need it to be.

Costing Information

Cost per Hour: This is where you can specify the cost of work center per hour.

Analytic Account: Fill this only if you want automatic analytic accounting entries on production orders. This will log movement in the work center along with performance and efficiency.

Smart Buttons

OEE: Overall Equipment Effectiveness, based on the last month.

Lost: This shows the total lost hours over the last month.

Load: This shows the total amount of work load in minutes over the last month.

Performance: This shows the performance over the last month.

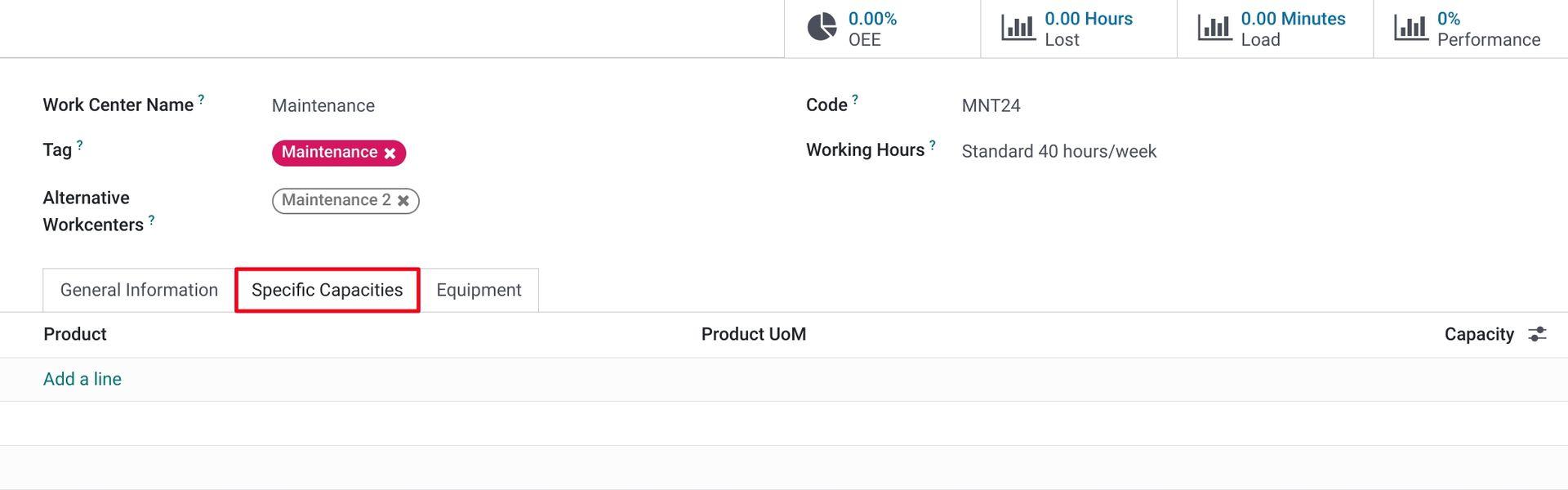

Under theSPECIFIC CAPACITIES tab:

This allows you to add a specific product that is used in this workstation location. To do this, click on ADD A LINE.

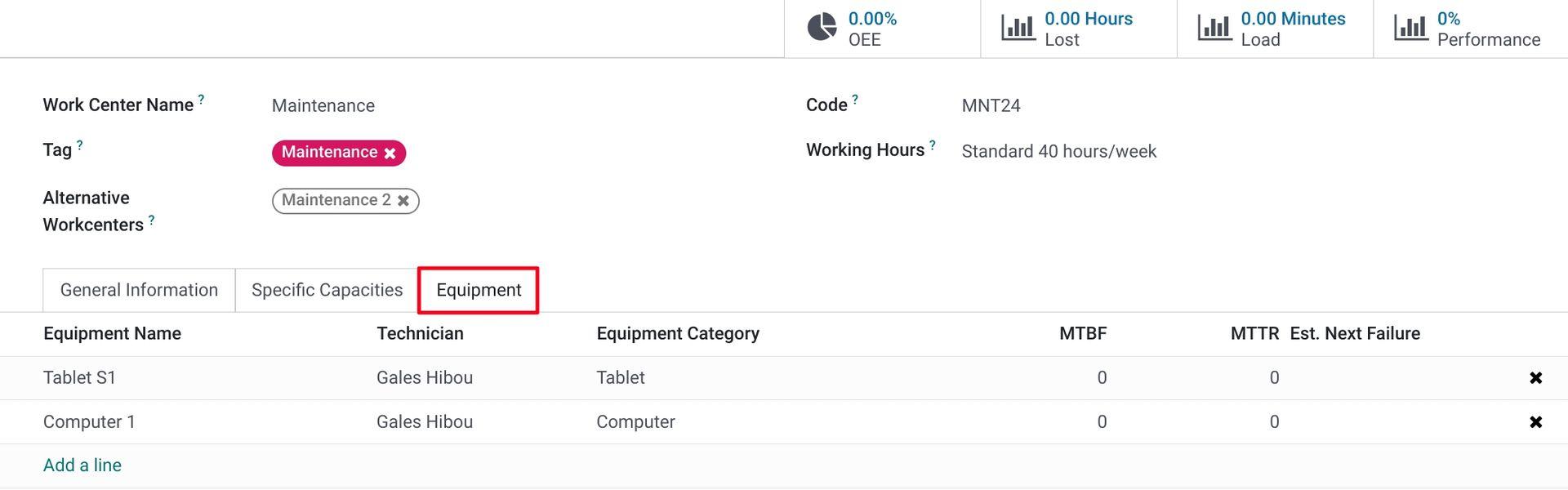

Under the Equipment tab:

This allows you to add in the equipment being used at this work center location. To do this, click Add A Line. Once you have finished setting up your work center, click to save.

For more information on Work Centers, see our documentation in the Manufacturing topic.